Products

~Things You Need to Know about Safety~

A power supply is a device that converts and provides electrical energy. It is designed and manufactured with utmost care for safety, but internally has electronic circuits that operate at high voltage (several hundreds of volts) and large current. Therefore, under wrong usage, it may cause abnormal heat and smoke, and in worst case, fire.

In this page, we will introduce examples leading to smoke and fire that are likely to occur according to various causes.

Also, please refer to instruction manual of individual product to ensure safe and proper usage

▶ 1.Avoid using beyond the lifetime

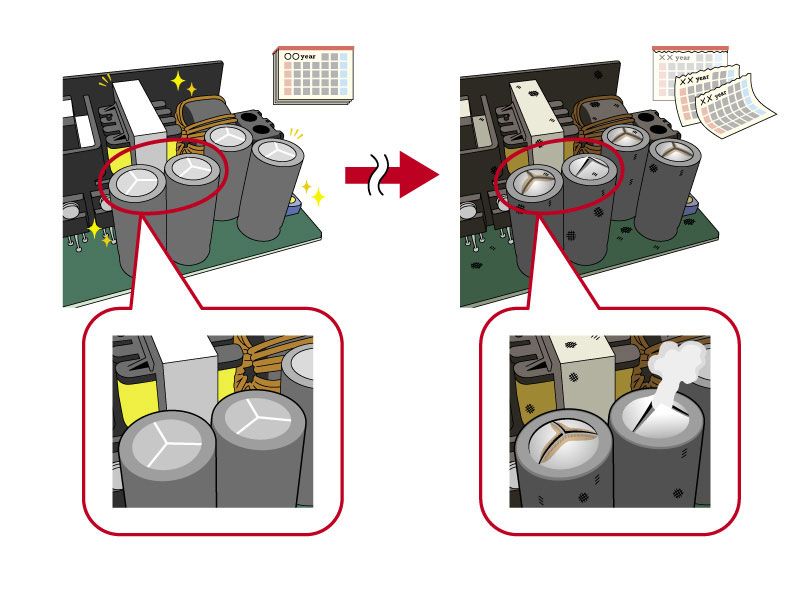

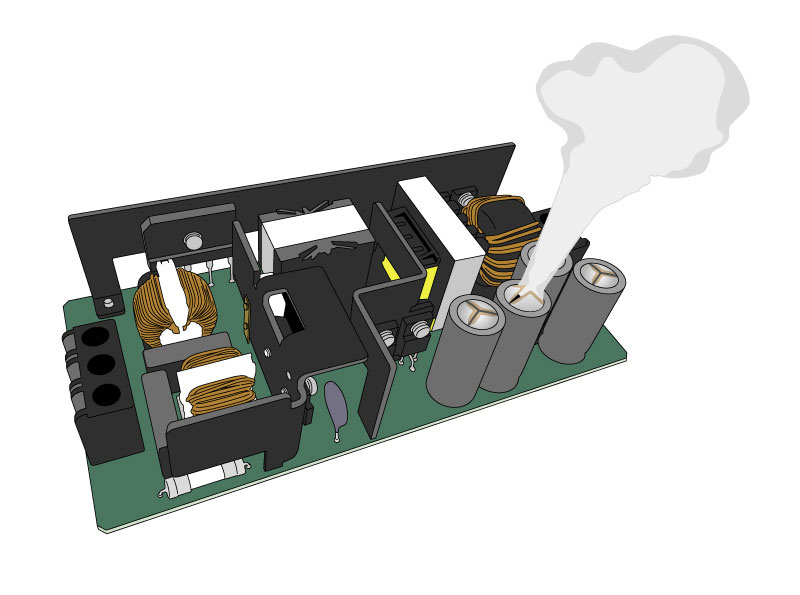

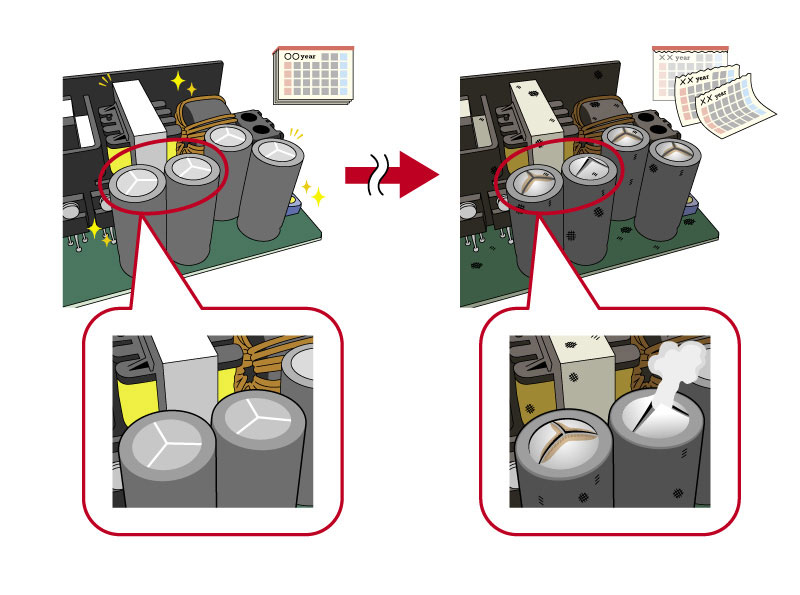

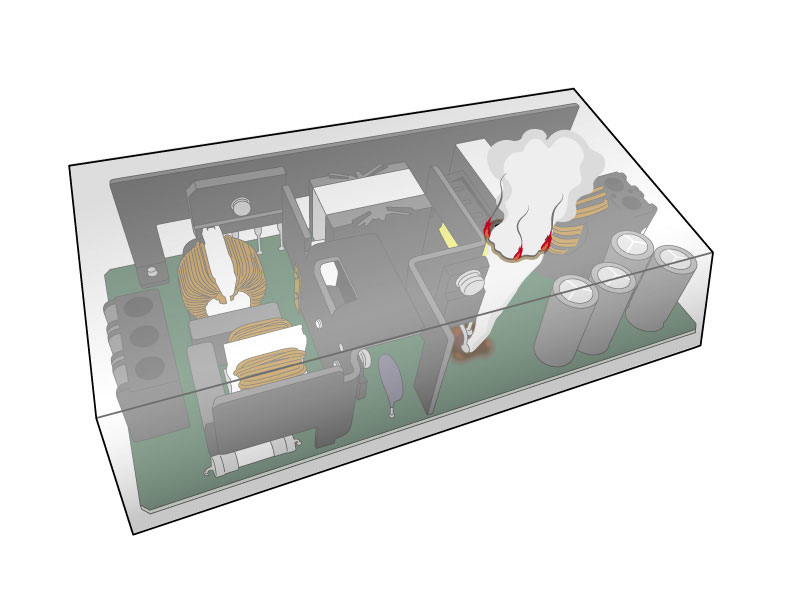

The life span of the power supply is generally determined by the lifetime of the electrolytic capacitor. At the end of life of the electrolytic capacitor, internal resistance increases causing abnormal heat which results into internal pressure build-up that forces the safety valve to open.

Gaseous electrolyte is released and liquid electrolyte may leak out from the terminal area.

- Due to long-term use, the airtightness of the electrolytic capacitor was lost, and the internal electrolyte leaked out.

This leakage created tracking path between patterns on the PCB board causing subsequent failures such as sparks and smoke.

- Before the power supply (electrolytic capacitor) reaches its end of life, replace it with a new power supply or overhaul it.

※Estimated life data of our each product are described in “Reliability data” (Electrolytic Capacitor Lifetime) posted on the website.

▶2.Avoid using under high temperature environment

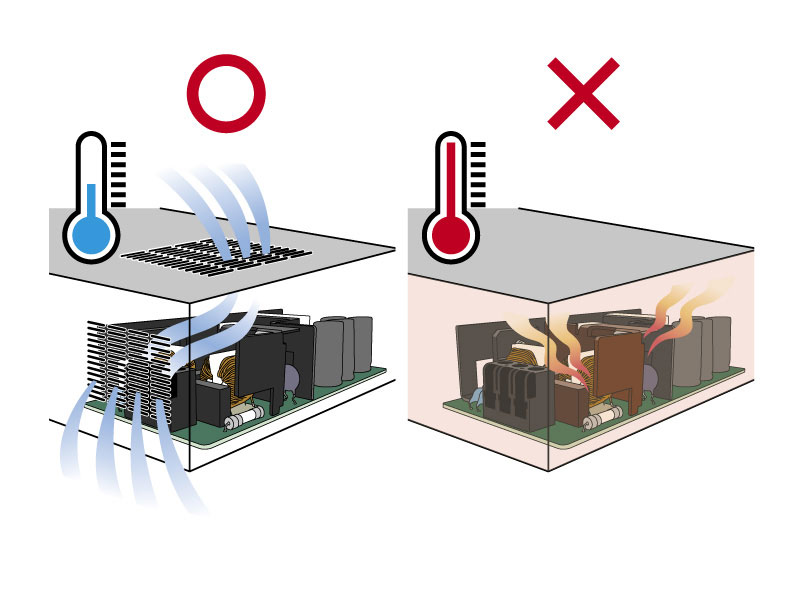

When used under high temperature environment, electrolytic capacitor life will be shortened. (In generaly, as the ambient temperature rises by 10°C, the life of the electrolytic capacitor decreases to about 50%) .

When the electrolytic capacitor reaches the end of its life, the capacitor may generate heat abnormally and cause an open valve failure (see item 1). Take care to reduce the power supply ambient temperature as much as possible.

- Since the air flow around the power supply was poor and the power supply was used in an ambient temperature beyond the allowable specification, causing the electrolytic capacitor reached its end of life earlier.

There were also cases where the electrolyte inside leaked out and created tracking path on the PCB board causing smoke emission.

- When designing mechanical structure for power supply mounting, be sure to provide as much as possible heat dissipation through convection or forced cooling methods around the power supply.

- The power supply must be used within allowable temperature range specified by the output derating characteristic curve.

▶3.Be careful about conductive foreign matter or contamination penetration

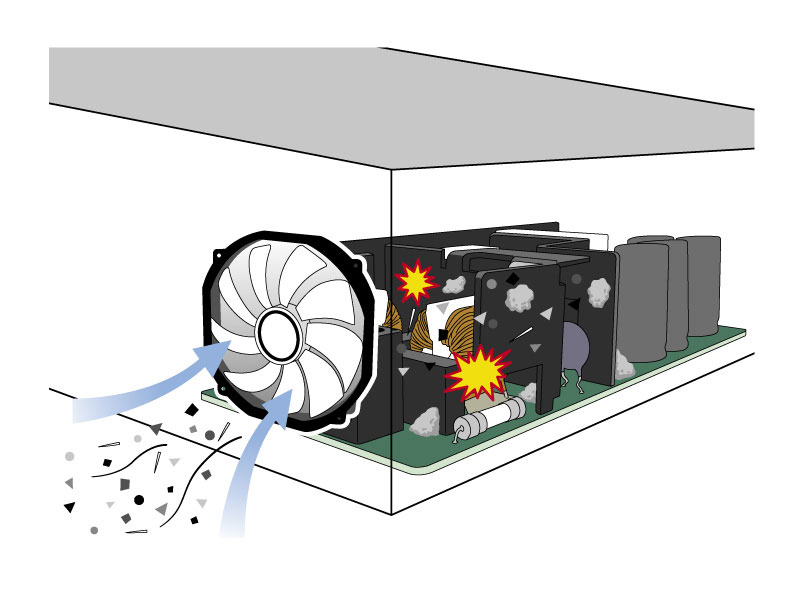

Fire or smoke emission from foreign matter inside the power supply might occur due to abnormal heat caused by spark ignition or tracking phenomena resulting from continuous electrical bias on unexpected path created by adherence of conductive foreign matter and dust to high potential areas (several hundreds of volts).

- Abnormal heat was generated at a high potential location due to mixture of metal pieces, dust, and liquid inside the power supply, resulting into substrate burn out.

- Dust accumulated inside the power supply and tracking phenomenon occured at high potential location, causing on the PCB board to emit smoke or burn out.

- Please consider installation environment to prevent foreign matter entering inside the power supply.

- For cases when temperature difference is large at installation environment, take preventive measures against possible dew condensation.

- Even non-conductive matters such as dust might turn conductive when it absorbs moisture from the air. Therefore, periodic overhaul (internal cleaning) is recommended to prevent trouble resulting due to conductive foreign matter.

▶4.Avoid placing flammable materials around the power supply

If flammable objects are placed around the power supply, unexpected carbonize may generation occurs due to an accidental failure of the power supply or any abnormality (tracking phenomenon or spark).

Fire might spread to these flammable objects, and may even spread to the casing of customer equipment.

※Take caution of the following flammable materials : relatively thin materials such as acrylic board, plastic board, paper, wood board etc.

- Power supply failure occurred when the power supply was placed in a plastic bag and installed in order to prevent end-user from touching the live part of the power supply. Eventually, the bag ignited and burned.

- A thin plastic plate was placed around a power supply to prevent electric shock during maintenance. The power supply failed and caused small spark from an internal component which ignited the plastic plate and then spread around the entire surrounding device enclosure.

- Avoid flammable objects from coming in contact with the power supply, as well as, installing these objects around the power supply. Avoid covering the power supply with flammable material. (Covering the power supply also interferes with ventilation and cooling (see Section 2))

- When separating the power supply and its surrounding area with an insulating plate or the like, use a highly flame-retardant material (Note that even if the material is the same, it can burn easily if it is thin)

▶5.Do not apply excessive mechanical stress

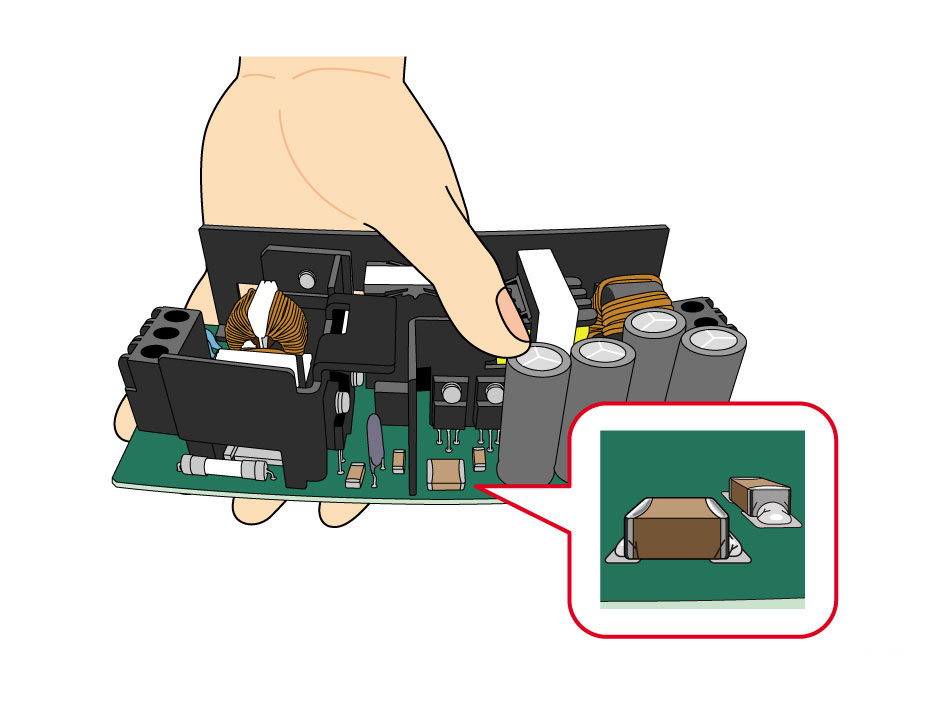

Mechanical stress while handling a power supply causes cracks in soldering and multilayer ceramic capacitors. The failure location may generate abnormal heat due to concentration of current caused by solder cracks or insulation failure due to capacitor cracks, and it will cause smoke or burnout.

- Dropping the power supply or applying shock caused microcracks in the multilayer ceramic capacitor. In this case, heat generation happened due to increased loss caused by insulation deterioration inside the capacitor. This caused the burning and tracking phenomena on PCB, it caused smoke emission and further damage.

- Do not use products that have undergone mechanical stress such as shock or the like.

- When handling the power supply, be careful not to apply an excessive external force to the mounted parts nor touch the mounted parts.

- Be careful not to distort or flex the power supply when mounting the device.

Please handle with special care when install the power supply because PCB type of power supplies easily flexes.