Neptune, NJ – October, 2022

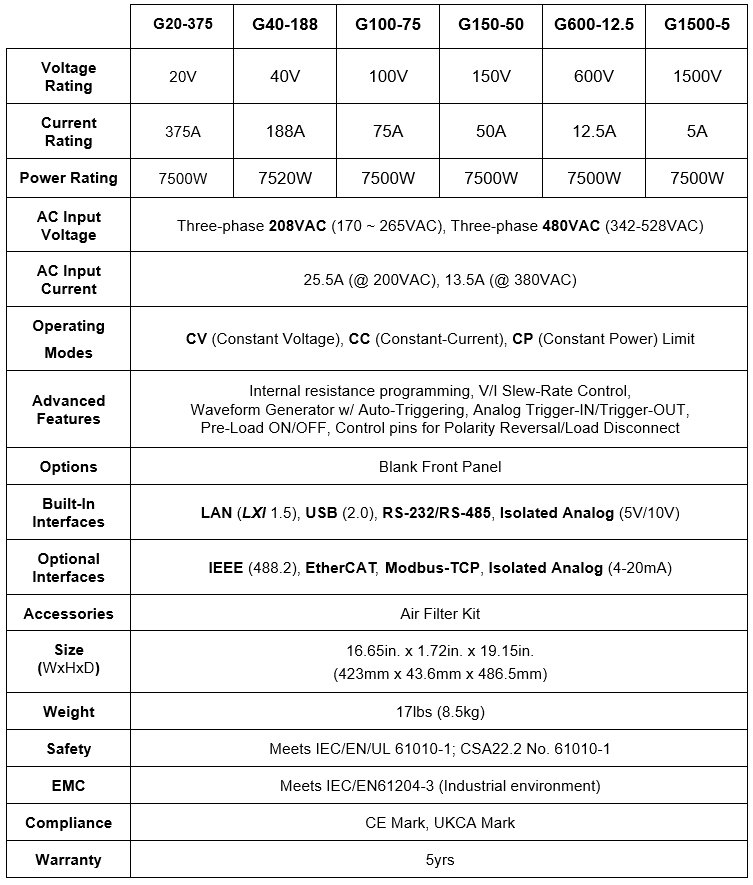

TDK Corporation (TSE:6762) announces the addition of the TDK-Lambda high power density 1U Full-Rack 7.5kW platform to the Advanced Programmable DC Power Supply Series. Six models are currently available from 20V-375A to 1500V-5A (20V-375A, 40V-188A, 100V-75A, 150V-50A, 600V-12.5A, 1500V-5A) and target the Automotive (eV and Hybrid Subsystem, Battery & Component Test), Renewable Energy, Industrial and Applied Research & Development market segments.

Built into a 1U (1.75”) high, 19” (423mm) wide, and 19.2” (486.5mm) deep bench-top/rack-mount mechanical profile, the 7.5kW Programmable DC Power Supply platform offers the highest power density and high efficiency (up to 92%) in a lightweight package (17lbs/8.5kg) with cooling fan speed control (for reduced audible noise and extended life).

All models offer three-phase AC Input options of 208VAC (170~265VAC) or a wide-range 480VAC (342~528VAC) with built-in Power Factor Correction (0.94 typical) and are capable of Constant-Voltage (CV) and Constant-Current (CC) mode operation with automatic crossover between operating modes.

The 7.5kW platform offers several advanced adjustable user-selectable functions including Constant-Power Limit operation, Internal Resistance simulation, and Slew-Rate control of Output voltage/current. Waveform profiles, such as vehicle battery start-up simulation, of up to 100 steps can also be generated and stored in four on-board memory cells and can be recalled and activated via the front panel display embedded menus or Remote Digital communication.

Standard safety features include user-selectable Safe-Start/Auto Re-Start, Last Setting Memory along with various built-in protective functions such as Output Over-Voltage Protection (OVP), Output Under-Voltage Limit (UVL), Output Under-Voltage Protection (UVP), Fold-Back protection (FOLD) for CV or CC mode, Output Over-Current Limit (OCL) and Over-Temperature protection (OTP).

Local/Remote interfacing is common across the entire product platform (1kW to 15kW) by multiple methods. These include local front panel control, remotely via the built-in LAN (LXI 1.5), USB (2.0) or RS-232/RS-485 Remote Digital interfaces or by use of the built-in Isolated Analog Program/Monitor/Control Interface. Optional rear panel Remote Digital Interfaces include either the IEEE (GPIB), Modbus-TCP or EtherCAT Interface. Instrument software drivers are also available as well as application software that includes a Waveform Creator (to create, store/load and trigger waveform sequence profiles) and a Virtual Front Panel GUI (with Status Logger, Constant Power Limit simulator and Solar Array simulator).

A new Advanced Parallel Primary/Follower system allows for improved multi-unit system performance (Output ripple/noise and dynamic response) where up to four units can be connected in parallel and automatically configured by detection of the parallel data-link cable connections between units, with the Primary unit being the single point for programming, measurement and status of system load current.

Other mechanical options include a Blank Front Panel and an Air Filter Accessory Kit. The Blank Front Panel is available for applications where the front panel display and controls are not required, and only remote interfacing (Digital/Analog) is being implemented. The Air Filter Accessory Kit is available for both standard and blank front panel models, has a removable snap-in filter (for easy maintenance) and is provided to prevent dust entry into the power supply.

Other mechanical options include a Blank Front Panel and an Air Filter Accessory Kit. The Blank Front Panel is available for applications where the front panel display and controls are not required, and only remote interfacing (Digital/Analog) is being implemented. The Air Filter Accessory Kit is available for both standard and blank front panel models, has a removable snap-in filter (for easy maintenance) and is provided to prevent dust entry into the power supply.

The 7.5kW Programmable DC Power Supply platform has Safety certifications to IEC/EN/UL/cUL 61010-1 with CE and UKCA marking in accordance with the Low Voltage, EMC (IEC/EN61204-3; industrial environment) and RoHS Directives and carries a five (5) year warranty.

—–

For more information about the TDK-Lambda Programmable DC Power Supply Series, please visit the TDK-Lambda Americas Programmable Power Supplies webpage at https://www.us.lambda.tdk.com/products/programmable-power/genesys-plus.html or fill out an online Information Request at https://www.us.lambda.tdk.com/contact/#contact.

Also available is the general-purpose GenesysTM Programmable DC Power Supply Series, the high power Programmable Rack DC Power Systems (30kW/45kW/60kW) and the Multi-Functional SFL 300W/1kW Programmable DC Electronic Load Series which can be viewed from the TDK-Lambda Americas website at https://www.us.lambda.tdk.com/products/programmable-power/.

Main applications

• Advanced Programmable DC Power Supplies for Automotive, Renewable Energy, Industrial, Medical and Applied R&D applications such as:

• Battery/component evaluation

• Solar Panel evaluation/test

• Subsystem and Component test/burn-in

• Medical Treatment systems

• Rack-mount ATE product validation

• Laboratory product/material research

Main Features and Benefits

• High power density (7.5kW in 1U 19” profile)

• Six models from 20V to 1500V ((20V-375A, 40V-188A, 100V-75A, 150V-50A, 600V-12.5A, 1500V-5A)

• Wide range three-phase 400V/480VAC Input (342-528VAC)

• High Efficiency (up to 92%) and high Power-Factor (0.94 typical)

• Lightweight (less than 17lbs/8.5kg)

• Embedded front panel setup menus: COMMunication, CONFiguration, PROTection, SYSTem and PROGram

• Constant-Voltage (CV), Constant-Current (CC) and Constant-Power (CP) Limit operation

• Internal Resistance Programming

• Up/Down Slew-Rate Control (Output Voltage/Current)

• Waveform Generator with Auto-Triggering (Store, Recall and Activation)

• Pre-Load ON/OFF Control

• Digital communication Watchdog Timer (user-selectable ON/OFF and timeout period)

• Fan Speed Control based on load current and ambient temperature (for reduced audible noise and extended fan life)

• Analog Over-Current Limit (OCL): user-selectable

• Output Control Pins (for Output polarity reversal/load disconnect)

• Enable/Disable Control (Signal or Dry-Contact) with user-selectable polarity

• Interlock ON/OFF Control (Signal or Dry-Contact)

• Analog Trigger-In/Trigger-Out signals

• Safety Features: Safe-Start, Auto-Restart, Last Setting Memory, Front Panel Lock/Unlock

• Protection Features: OVP, UVL, UVP, FOLDback (CV or CC), ENA, ILC, AC-Fail, OTP

• Parallel capability to 30kW (up to four units in parallel)

• Daisy-Chain Fault Shutdown Capability (for Multi-Unit Connection)

• Bench-top or rack-mount capability

• Front-to-Rear Airflow and Zero-Stacking

• Connector-style AC Input connections

• DC Output connections: busbar style or connector-style

• Built-in LAN (LXI 1.5), USB (2.0) and RS-232/RS-485 Digital Interfaces (w/ Multi-Drop capability)

• Built-in Isolated 5V/10V Analog Program/Monitor/Control Interface (w/ 600V isolation)

• Optional Digital Interfaces: IEEE (488.2), EtherCAT, Modbus-TCP

• Optional Analog Interfaces: Isolated Analog 4-20mA Interface (IS420)

• Blank Front Panel option (all models)

• Air Filter Kit (for standard front panel and blank front panel models)

• Safety: Meets IEC 61010-1, EN 61010-1, UL 61010-1, CSA22.2 No. 61010-1

• EMC: Meets IEC/EN61204-3, Industrial environment

• Five Year Warranty

Key data

About TDK Corporation

TDK Corporation is a world leader in electronic solutions for the smart society based in Tokyo, Japan. Built on a foundation of material sciences mastery, TDK welcomes societal transformation by resolutely remaining at the forefront of technological evolution and deliberately “Attracting Tomorrow.” It was established in 1935 to commercialize ferrite, a key material in electronic and magnetic products. TDK‘s comprehensive, innovation-driven portfolio features passive components such as ceramic, aluminum electrolytic and film capacitors, as well as magnetics, high-frequency, and piezo and protection devices. The product spectrum also includes sensors and sensor systems such as temperature and pressure, magnetic, and MEMS sensors. In addition, TDK provides power supplies and energy devices, magnetic heads and more. These products are marketed under the product brands TDK, EPCOS, InvenSense, Micronas, Tronics and TDK-Lambda. TDK focuses on demanding markets in automotive, industrial and consumer electronics, and information and communication technology. The company has a network of design and manufacturing locations and sales offices in Asia, Europe, and in North and South America. In fiscal 2022, TDK posted total sales of USD 15.6 billion and employed about 117,000 people worldwide.

About TDK-Lambda Corporation

TDK-Lambda Corporation is a trusted, innovative leader and global supplier of highly reliable power conversion products for industrial and medical equipment worldwide.

TDK-Lambda Corporation is aligned for fast responses to any customer need with R&D, manufacturing, sales and service locations in five key geographic regions, namely Japan, EMEA, Americas, China and ASEAN.

For more details, please pay a visit to www.jp.lambda.tdk.com/en/

Downloads

• Product with background (jpg)

• Product without background (jpg)

• Press release (pdf)

More product info

Please click here